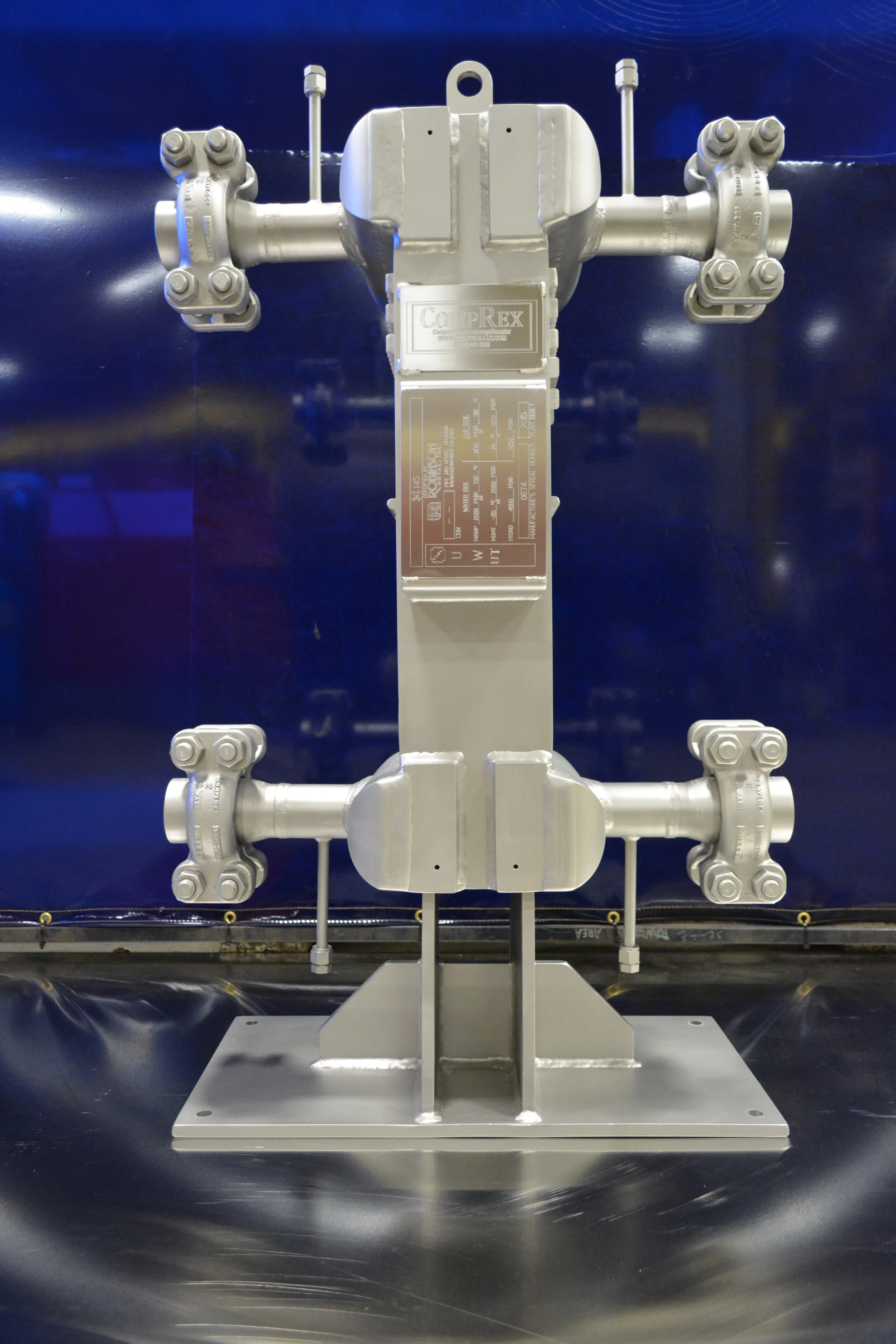

In August 2014, CompRex, LLC (De Pere, Wisconsin) was awarded a contract from the Naval Nuclear Laboratory to design, engineer, and fabricate a diffusion bonded, stainless steel heat exchanger for supercritical CO2 power cycle development. In August 2015, CompRex, previously announced the successful completion of a hydrostatic pressure test of a representative heat exchanger. Today CompRex announces the completion of yet another milestone. Recently, the Naval Nuclear Laboratory completed the initial thermal-hydraulic performance testing of a CompRex heat exchanger and provided test results to CompRex. The test results exceeded the expected design performance and provide additional proof that the CompRex design and construction methods are suitable for producing commercial size heat exchangers for supercritical CO2 service. These units are designed and engineered by CompRex and manufactured at Robinson Metal in De Pere, Wisconsin. The following photograph shows the heat exchanger tested.

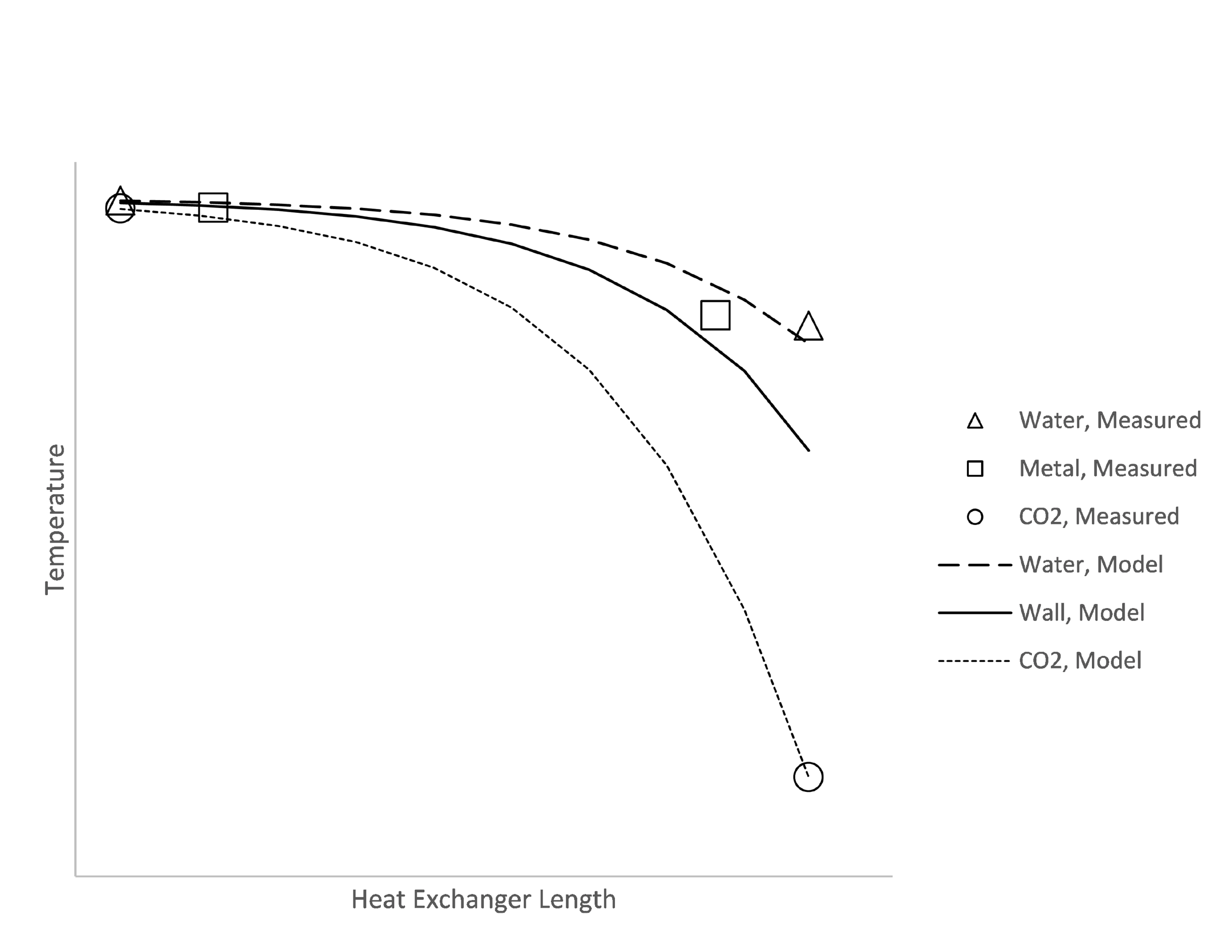

The thermal performance of the heat exchanger was excellent with the measured transfer between 95-98 percent of the maximum heat transfer.

The flexibility of the CompRex fabrication technique allowed placement of thermocouples within the walls between the fluids in order to measure the wall temperatures. The measured wall temperatures were consistent with the modeled wall temperatures as shown in the first plot on the next page.

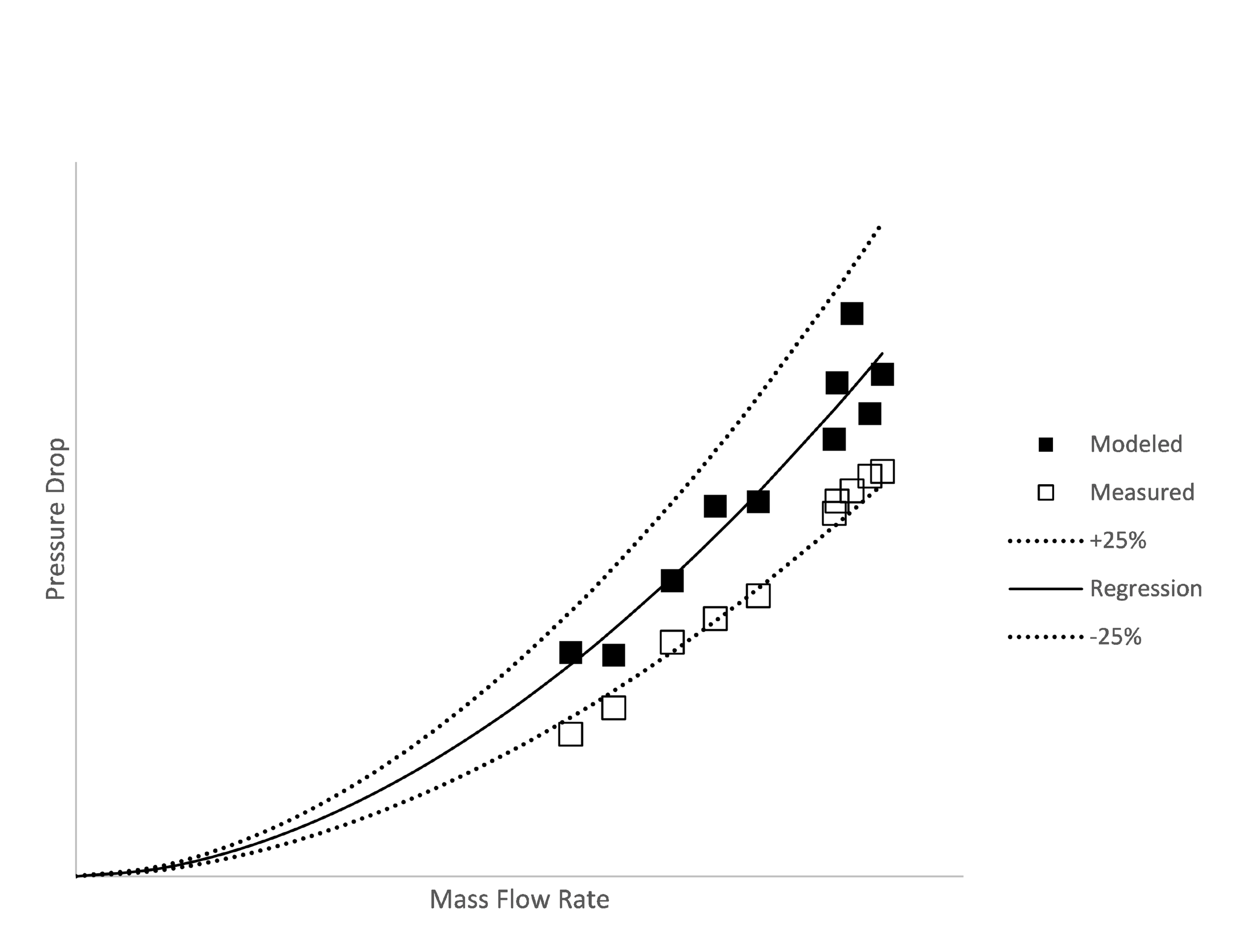

The measured pressure drop values for the CO2 stream were almost all within ±25 percent of the modeled pressure drop values, as shown on the second plot on the next page. In addition, the measured values were consistently less than the modeled values.

"We are pleased with the successful thermal and hydraulic performance test of this unit. These results come after the successful mechanical testing of CompRex's ShimRex® geometry completed last year. Now that both the mechanical and thermal-hydraulic performance testing have been successfully completed, CompRex is confident that the custom engineered, ShimRex®, diffusion bonded, stainless steel heat exchangers are a proven and suitable solution for supercritical CO2 applications. This unit is just one of many diffusion bonded heat exchangers and chemical reactors which CompRex can supply to industry and development teams in support of supercritical CO2 power cycle development," commented Zhijun Jia, CEO of CompRex, LLC.

CompRex is a United States based, technology leading, independent manufacturer of highly engineered, brazed and diffusion bonded heat exchangers and chemical reactors. The CompRex units are custom engineered to offer the desired performance of many processes that can benefit from highly efficient and compact technology. CompRex is proud to partner with Robinson Metal, Inc. which oversees all CompRex Product manufacturing. Robinson Metal also fabricates skids and custom enclosures for all modular systems designed by CompRex. With CompRex's strong heat exchanger and chemical reactor knowledge and design capabilities, and Robinson Metal's strong manufacturing and fabrication capabilities, together they are able to provide custom designed and integrated systems to meet our client's needs.