Complex Problems? CompRex Solutions.

Compact Heat Exchanger and Reactor Solutions

SCROLL DOWN

Complex Problems? CompRex Solutions.

Compact Heat Exchanger and Reactor Solutions

Overcoming Limitations

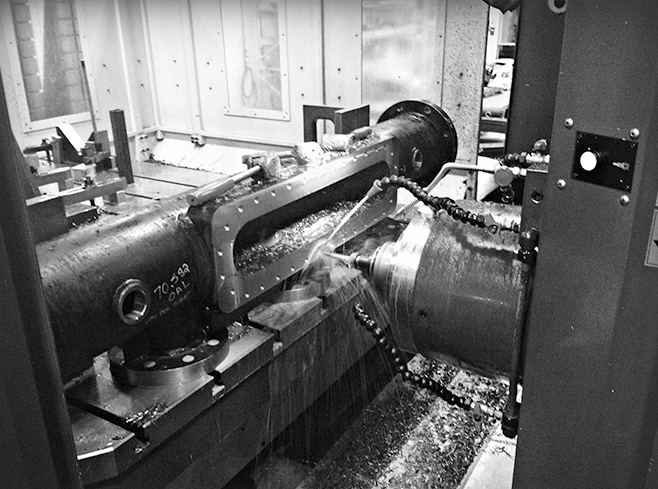

CompRex offers custom compact heat exchanger and heat exchanger reactor solutions for operation at extremely high temperature and or high pressure conditions.

Our innovations in material, design, and manufacturing processes allow our products to not only withstand such extreme environments but offer superior efficiency and cost effectiveness at the same time.

CompRex also offers an innovative solution for wastewater treatment with PFAS removal in a supercritical water oxidation process using compact heat exchanger reactors and compact heat exchangers.

Enabling Breakthroughs

CompRex’s products are critical for power generation, water filtration, petrochemical production, and waste treatment.

Enabling Breakthroughs

CompRex’s products are critical for power generation, water filtration, petrochemical production, and waste treatment.

Most industrial processes today rely on exothermic reactions through which energy is released to the surroundings in the form of heat, and for many such reactions, their efficiency increases further when operated at higher temperatures. However, the bottleneck to realizing these efficiency improvements is in heat exchange: all this excess heat has to be removed promptly, otherwise it can actually reduce operational efficiency and negatively affect system integrity. This is the bottleneck that CompRex seeks to resolve, with benefits across a wide range of applications.

Realizing Potential

Our dream is to change the world for the better. We have both the technology and the people to do it.

Realizing Potential

Our dream is to change the world for the better. We have both the technology and the people to do it.